Conformal Coating

EMLINQ SERVICES CONFORMAL COATING

At EMLinQ, we provide conformal coating services to protect electronic assemblies from harsh operating environments, extending product life and reliability. With facilities in both Simi Valley, California and Mexicali, Mexico, we offer customers flexibility in handling both prototype volumes and scalable production runs while ensuring coating processes meet the highest industry standards.

Protecting What Matters

Conformal coatings form a thin, protective barrier over PCBs, safeguarding them against moisture, dust, chemicals, and temperature extremes. EMLinQ applies coatings tailored to your application, whether it’s for industrial, aerospace, IoT, lighting, or renewable energy electronics. Our expertise spans:

- Acrylic, silicone, and urethane coatings

- UV-curable and hybrid chemistries

- Spray, selective-coating, and dip processes

- Masking and de-masking of connectors and keep-out areas

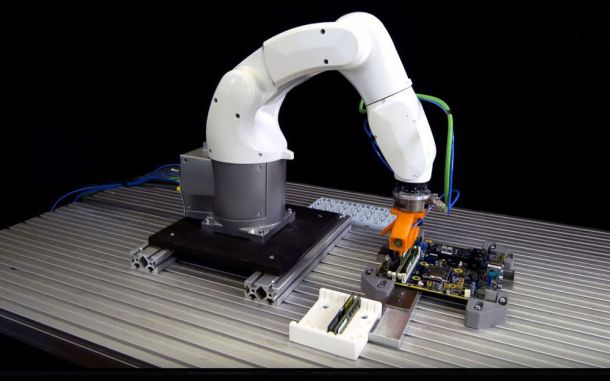

Advanced Process & Equipment

Our facilities are equipped with a Nordson automated conformal coating system, enabling precise, repeatable, and efficient coverage. This technology ensures consistent protection while reducing material waste and cycle time. For assemblies requiring targeted protection, we combine automated coating with manual touch-up and inspection, ensuring 100% coverage without compromising functionality.

Quality & Compliance

- All coatings are applied to IPC-CC-830 standards and inspected under UV lighting and magnification.

- We conduct adhesion, thickness, and cure validation testing to guarantee consistency.

- Our engineering team leverages DFM tools, including Valor™, to assess board design for coating accessibility and process optimization before production begins.

Why EMLinQ

- Dual-facility footprint for rapid proto support and cost-efficient production

- Expertise across coating chemistries and application methods

- Integration with PCBA assembly, cable harnessing, and box build services

- Process control and testing to ensure long-term reliability

At EMLinQ, conformal coating isn’t just a value-add step — it’s a critical layer of protection engineered to extend product durability in demanding real-world environments.

Related Services

Prototype Builds

EMLinQ provides quick turn prototype manufacturing, including small quantity runs...

System Assembly

EMLinQ provides full turnkey PCB assembly, complete functional tests, burn-in, and final packaging...

Cable Assembly

EMLinQ, with a high volume KOMAX and Schlienberger machines, provides capabilities to address both...